A d v a n c e d A u t o M a i n t e n a n c e

Bypass engine oil filtration...

Thanks a lot to Jim Elkins of Jackmaster Oil Filters at jackmasteroilfilters.com.au who provided me with a lot of authoritative information on engine oil for this section based on his depth of experience and expertise in this area.

At the bottom of this web page are seven (7) extremely high resolution images of a bypass engine oil filtration installation that I have completed on a front-wheel drive 1986 Toyota Camry SV11 which had a 2.0 litre engine with electronic fuel injection (EFI). These images total about 21 megabytes in size, on account of the limited experience of the author of this website using a digital camera and on account of the hurried manner in which he captured the images. These images were captured in February, 2011, two and a half years after the author of this website first installed this bypass engine oil filtration system in August, 2008.

It should be obvious by now that conventional full-flow engine oil filtration is far from ideal. Bypass filtration is a vastly superior form of filtration which is used in conjunction with full-flow conventional engine oil filtration. While the engine oil still cycles throughout the engine via the full-flow filter in the normal way, the use of additional bypass filtration involves diverting a portion of the oil from this cycle to a thick, tightly-wound cellulose bypass filter element which is essentially like tightly-wound tissue paper and is much finer and denser than the conventional full-flow paper filter.

The bypass filtration material is contained within a strong, synthetic, outer mesh to ensure that none of it ever breaks off and finds its way into the oil and into the engine. After the oil has passed through the bypass filter, it returns to the engine (eg. via an oil hose connecting through the oil cap) and rejoins the oil circulating around engine.

The bypass filter element removes all particulate contaminants larger than 3 microns in size from the engine oil, as well as all water, whereas a conventional full-flow filter fails to remove a significant percentage of particulate contaminants less than 30 microns in size and fails to remove any water from the engine oil. The result of bypass filtration is immaculately clean engine oil all of the time and dramatically improved engine performance. The interval for draining and replacing the engine oil can be increased from every three months or 5,000 kilometres (3,000 miles), whichever comes first, to every 50,000 kilometres (30,000 miles).

Bypass engine oil filtration succeeds where conventional engine oil filtration fails…

Whereas a typical full-flow filter can remove most particles larger than 30-40 microns in size but still lets a large percentage of particles smaller than 30 microns through, a bypass filter removes the following contaminants from the engine oil:

- All metal particles, atmospheric dirt or dust and carbon larger than 3 microns in size. In addition, a significant percentage of these particulate contaminants which are less than 3 microns in size are also removed after they re-circulate through the bypass filter.

- All water that finds its way into the oil having been blown past the piston rings as a by-product of combustion or via condensation inside the engine. Whereas a typical full-flow filter doesn’t remove any water from the oil, a bypass filter removes all of it by absorbing it like a sponge.

- All sludge that forms in the oil as a result of the chemical additives in the oil decomposing and solidifying due to the oxidation of the oil over time (ie. chemical reaction with oxygen) as a result of the high temperatures that exist inside the engine.

When only full-flow filtration is used, these solids contaminate the engine oil and then coat themselves on the moving parts inside the engine as a form of varnish, which reduces the clearances between these parts and increases friction. However a bypass filter prevents this varnish from forming at all on moving parts inside the engine by removing the sludge completely from the oil.

Bypass filtration removes the overwhelming majority of contaminants that full-flow filtration cannot so that the oil is effectively made as clean as it was when it was poured into the engine from its packaging. Because the smallest clearances in the engine are about 5 microns in size and because bypass filtration removes all particulate contaminants larger than 3 microns in size, wear in the engine is virtually eliminated altogether. Any remaining particulate contaminants smaller than 3 microns in size are simply suspended in the oil film between the moving parts which prevents them from causing wear.

Bypass engine oil filtration results in much longer engine oil drain intervals...

Bypass filtration filters all the engine oil over the course of about ten minutes while the engine is running which equates to about six times every hour of driving. This means that engine is continually receiving immaculately clean oil. Because the oil is being continually cleaned, it can be left in the engine for much longer than is permissible under conventional full-flow filtration alone where the engine oil should be drained and replaced after 3 to 4 months or 5,000 kilometres (3,000 miles), whichever comes first, to minimise engine wear.

Engine oil that is continually filtered with a bypass filter can be left in the engine for 50,000 kilometres (30,000 miles) before replacing it with fresh oil. This results in a substantial saving of time (ie. the hassle of getting the engine oil changed or changing it yourself) and money (ie. the cost of fresh engine oil and the cost of labour if you normally pay a mechanic to change the oil).

Because the engine oil gets topped up regularly over the course of this 50,000 kilometres (30,000 miles) as a result of some oil normally escaping past the piston rings into the combustion chambers and expelled through the exhaust, there’s enough fresh oil being added to keep the additives in the engine oil at an adequate level so that they don’t become depleted.

By continually removing contaminants from the engine oil using bypass filtration, the oil can be used for a full 50,000 kilometres (30,000 miles) and it protects the engine from wear over this entire distance. It’s important to change the bypass filter element (which costs just $10 or less) regularly over this time, every 5,000 to 15,000 kilometres (3,000 to 9,000 miles). Personally, I recommend that this element be changed at the lower end of this range, every 5,000 kilometres (3,000 miles).

It’s important to note that no drop in oil pressure results from the diversion of oil through the bypass filter because the bypass system (including the canister that holds the bypass filter element) is filled up with a constant volume of oil at all times, whether the engine is running or not. This means that the oil capacity of the engine actually increases as a result of installing a bypass filter since oil needs to be added to the engine in order to fill up the empty space inside the newly installed bypass system, including the canister that holds the bypass filter element.

The advantage of increasing the oil capacity is that there is more oil in the engine to do all the things it’s supposed to do, such as lubricate, clean and transfer heat away from moving parts. Because there’s more oil, it can do all of these things more efficiently.

Benefits of bypass engine oil filtration…

Here’s a summary of the benefits of using a bypass engine oil filtration system in addition to conventional full-flow engine oil filtration:

All particulate contaminants larger than 3 microns in size are removed…

All particulate contaminants in the oil such as metal, dirt and carbon larger than 3 microns in size are filtered out by the bypass filter. In addition, a significant percentage of these particulate contaminants less than 3 microns in size are also removed after they re-circulate through the bypass filter. The result is that engine wear is virtually eliminated altogether, causing the engine to last longer and develop fewer (if any) problems, which results in dramatically lower motoring costs.

The engine oil is continually kept clean…

The engine is continually operating with immaculately clean oil which is cleaner than the oil could ever be under conventional full-flow filtration alone. Under the scenario of a change of oil under full-flow filtration alone, when the oil is drained there are still contaminants left behind inside the engine casing that the full-flow filter wasn’t able to remove from the drained oil when it was in use and won’t be able to remove from the fresh oil either that’s added to replace it. However bypass filtration most definitely does remove the overwhelming majority of these contaminants. Therefore bypass engine oil filtration results in cleaner oil than if the oil has just been changed under conventional full-flow filtration.

Increased removal of carbon from the engine oil…

The increased removal of carbon from the engine oil under bypass filtration reduces the unwanted phenomenon of the carbon absorbing the chemical additives in the oil that promote lubrication and cleaning. This resulting in better performing oil that lubricates better and cleans better.

All water is removed from the oil…

All water in the oil (which is blown past the piston rings into the oil as a by-product of combustion or which results from condensation inside the engine) is removed from the oil through absorption by the dense, bypass filter element. This prevents corrosive acids, such as nitric acid and sulphuric acid, from forming in the oil and damaging engine parts. It also prevents the lubricating ability of the oil from being diluted and degraded by the presence of water.

All sludge is removed from the oil…

All sludge is removed from the oil which prevents varnish from forming on moving engine parts so that friction is reduced.

Reduced friction means smoother engine operation…

The reduced friction between moving parts inside the engine as a result of the increased removal of particulate contaminants and the prevention of the formation of varnish on moving parts results in an increase in fuel economy and in power output. Cleaner oil results in better fuel economy and more responsive power because the engine doesn’t have to push a whole lot of contaminants around with the engine oil.

This is the same as the smoothness and responsiveness that can be felt in an engine that only uses full-flow filtration and that has just had its oil changed. However, under bypass filtration, the smoothness is even more noticeable, because the oil is even cleaner. It can also be felt all of the time, whereas under conventional full-flow filtration alone, the oil soon becomes contaminated after the oil is changed and the smoothness in the engine gives way to noisier and harsher operation.

Oil change intervals increase dramatically...

Because the oil is continually kept immaculately clean by the bypass filter, you can leave it in engine for 50,000 kilometres (30,000 miles) before replacing it with fresh oil. This dramatically extended oil change interval results in a substantial saving of time and money normally associated with frequent oil changes under conventional full-flow filtration every three to four months in order to minimise engine wear.

Time and money that would otherwise need to be spent attending to oil changes can be directed towards other aspects of your vehicle’s maintenance. You can actually forge ahead with other planned auto maintenance or improvements and ensure that the condition of the vehicle steadily improves. How’s that for a paradigm shift? As time goes on, the condition of the vehicle can steadily improve rather than gradually deteriorate!

Replacement of the full-flow filter is less frequent…

Because the oil is continually kept immaculately clean by the bypass filter, the full-flow filter doesn’t need to be changed as often as it normally would under full-flow filtration alone since it doesn’t get clogged with contaminants nearly as quickly. It’s sufficient to change the full-flow filter just once per year.

The oil capacity of the engine is increased…

The oil capacity of the engine is increased in order to fill the space inside the bypass system, including the canister which holds the bypass filter element. This increased oil capacity results in more efficient lubrication, cooling and cleaning by the oil.

My experience with bypass engine oil filtration...

I installed a bypass engine oil filter onto my vehicle in August, 2008. Because I was very busy at the time, I even left the existing, used engine oil in the engine and let the bypass filter mop up the contaminants in it. I was interested to see how the bypass filter would handle this contaminated oil.

After idling the engine for ten minutes and then driving for a short time, I noticed that the engine was running much more briskly than before the bypass filter was installed. The reason for this was that prior to the installation of the bypass filter, the engine oil was significantly contaminated and ready to be changed. Dirty engine oil like this always results in a noisier, more sluggish engine. However the bypass filter cleaned the oil up very quickly so that the engine operated just as smoothly as when the engine oil is replaced with fresh oil.

The resulting benefits that I noticed were better acceleration (since the engine wasn’t pumping the contaminants in the engine oil around anymore which had now been captured by the bypass filter), better fuel economy (since less energy was required by the engine to pump the clean engine oil around) and a noticeably quieter engine.

Three weeks later I changed the bypass filter element because it had become saturated with the contaminants that it had filtered out of the engine oil. I’d noticed that the engine was no longer as silky smooth as when I first installed that new bypass filter element. When I removed the element, it was black. After installing another new bypass filter element, the engine began to run better than ever. I get the impression that the cleaner oil was resulting in long-standing varnish being cleaned off of the moving components in the engine, which gave rise to better engine performance.

Bypass engine oil filtration maintenance schedule…

The way I maintain the bypass filtration system on my vehicle is as follows:

- Change the bypass filter element every 6 months or 5,000 kilometres (3,000 miles), whichever comes first.

- Change the full-flow filter every 12 months or 10,000 kilometres (6,000 miles), whichever comes first.

- Change the engine oil every 60 months or 50,000 kilometres (30,000 miles), whichever comes first.

Note that the extended service interval for the full-flow filter is possible as a result of the bypass filter continually keeping the engine oil immaculately clean. As a result of this clean oil, the full-flow filter collects far fewer contaminants than if the bypass filter weren’t used. Therefore the full-flow filter doesn’t need to be changed as often.

Bypass engine oil filtration saves time and money...

By following the routine above I’m keeping the engine oil in my vehicle continually immaculately clean and saving myself about 2.8 oil changes per year, since I’d need to change the oil every four months (ie. 3 times per year) in order to keep it as clean as possible without the assistance of a bypass oil filter.

So instead of needing to change my engine oil fifteen times over the course of a five year period, I only have to change it once. The amount of money that I’m saving over a five-year period is considerable. Here’s the breakdown of the savings:

- 14 x engine oil flushes not required resulting in a saving of $182.

- 14 x engine oil fills not required resulting in a saving of $560 based on 4 litres/quarts of oil per fill and $10 per litre/quart of oil. (This is the cost of the high-quality Nulon synthetic oil that I use.)

- 10 x full-flow filters not required resulting in a saving of $150.

- 10 x bypass filter elements required resulting in a negative saving (ie. expenditure) of -$100.

This is a total saving of $792 every five years or $158.40 every year, not to mention the time I save by not having to perform fourteen extra oil changes every five years, which take me about three hours each when I factor in the time it takes to purchase the parts and the time it takes to dispose of the used engine oil. I can think of many things I would rather be doing on the weekend than changing the engine oil.

In fact, this savings breakdown that I’ve calculated above assumes that the cost of labour of changing the oil is nil, because I change the oil myself. If you need to take your vehicle to a mechanic to get the oil changed, the amount of money you’ll save by having a bypass filter is much greater. It’s a saving of an additional $140 per year (based on a conservative labour cost of $50 per oil change) resulting in a total saving of $298.40 per year.)

Engine oil changes every 50,000 kilometres (30,000 miles) is conservative…

These are substantial savings of money, time and inconvenience. The amazing thing is that the way I’m choosing to maintain my bypass filtration system is quite conservative. There are people out there who are changing their bypass filter elements every 15,000 kilometres (9,000 miles), their full-flow filters every 80,000 kilometres (50,000 miles) and their oil every 800,000 kilometres (500,000 miles) or more! Consider the following example of a 1990 Peterbilt diesel truck which is fitted with a bypass filter and has more than 1,600,000 kilometres (1,000,000 miles) on the clock using these extended service intervals:

gulfcoastfilters.com/1,000,000%20MILES.htm

The bottom line in this example is that the engine in this truck, when disassembled and inspected after 1,600,000 kilometres (1,000,000 miles), was very clean and had only marginal wear on the piston rings where the clearance to the cylinder walls is very fine. No other wear could be found, which makes perfect sense since the bypass filter is removing all particulate contaminants of 3 microns in size or larger.

It’s important to note that it’s a good idea to use oil analysis if you want to extend the service interval for changing the engine oil beyond 60 months or 50,000 kilometres (30,000 miles), whichever comes first. Oil analysis, whereby you send a sample of your engine’s oil to a laboratory for analysis and receive a report on its health, enables you to make an informed decision about whether to keep using the same engine oil or replace it. Oil analysis becomes more significant in the case of fleet management or where trucks with large oil capacities are being run.

In my case of running a passenger vehicle with a 2.0 litre (122 cubic inch) engine and a small oil capacity, it makes more sense for me to simply change the oil altogether after 60 months or 50,000 kilometres (30,000 miles), whichever comes first, rather than incur the expense of using oil analysis. Another reason that I change the oil using this service interval is that I would rather reset my bypass filtration system with fresh engine oil than try to get the greatest possible mileage from one oil change.

I’ve got no doubt whatsoever that it’s possible to run a vehicle on the same oil without ever changing it when a bypass filter is used with absolutely minimal resulting engine wear, as is evidenced in the example above of the truck with 1,600,000 kilometres (1,000,000 miles) on the clock and only one oil change. However the oil does darken with age as a result of sub-micron carbon particles being deposited into the oil that even the bypass filter can’t remove. It sits more comfortably with me to replace the engine oil with fresh oil every 60 months or 50,000 kilometres (30,000 miles), whichever comes first, than it does to keep using that same engine oil ad infinitum.

I use and recommend the Jackmaster bypass oil filter system…

For the following reasons, I use and recommend the Jackmaster bypass oil filter system which can be found at jackmasteroilfilters.com.au.

- The filter canister is of high-quality and sturdy construction, as are the other components in the system.

- It’s reasonably priced. The system for my vehicle cost around $300 for all of the parts required.

- The replacement bypass filter elements are of good quality and are very economically priced at about $10 each. This makes them dramatically less expensive than spin-on bypass filters.

- The bypass filter elements are easy to change and allow you to see the condition of the filter element and the contaminants that have been trapped. In contrast, spin-on bypass filters don’t allow you to see the condition of the filter element or the contaminants that have been trapped.

- The Jackmaster bypass filter accepts bypass filter elements from other bypass filter manufacturers such as Frantz Filters and Kleenoil.

- The return of the bypass-filtered oil to the engine via the oil cap allows you to check at any time that the system is functioning correctly and producing cleaned oil by unscrewing the oil cap and checking that the cleaned oil is being output while the engine is running.

Installation of a bypass engine oil filter…

The first stage of the installation of a bypass filter is identifying where to locate the bypass filter and then constructing the bracket on which it’s going to be mounted. This is the most challenging and time-consuming aspect of the entire installation. Mounting the bypass filter properly so that it doesn’t interfere with other components in the engine bay and so that they don’t interfere with it is the most important aspect of the installation.

I was determined to set my own bypass filter system up so that it could be relied upon to operate faultlessly over the long term. My engine bay has a very limited amount of space so the biggest challenge was finding a place to locate it. After racking my brains, I realised that the best place to put it was next to the battery, mounted onto a right-angle bracket held down by the weight of the battery and by the battery bracket which holds the battery down.

The second stage of the installation is connecting the oil hoses from the engine to the bypass filter canister and from the canister back to the engine via the oil cap. The oil hose from the engine can be connected to the engine via the threaded hole where the oil pressure switch is located. (The oil pressure switch is relocated using a brass tee-piece between the oil hose and the engine.) It’s very important to set the system up so that no oil leaks occur in the several joins between different components through which oil flows.

Here are some important tips based on the installation of the Jackmaster bypass filter system on my vehicle:

Obtain another oil cap…

Obtain another oil cap to be drilled through and set up with the hose returning filtered oil to the engine so that you don’t have to drill through the original oil cap.

Remove all debris thoroughly from the oil cap after drilling through it…

Use a spherical grinding bit in an electrical drill to remove all burrs from around both sides of the hole drilled through the oil cap. Wash the oil cap thoroughly with water under pressure after using the grinding bit so that there’s no chance of plastic or metal filings from around the hole falling into the engine and causing damage.

Use string to determine how long the oil hose needs to be…

Use string to determine how long an oil hose needs to be. Using string enables you to follow what is often the curvaceous route that the flexible oil hose will need to take.

Don’t damage the threaded hole in the engine block…

It’s important to be very careful when screwing any component into the hole in the engine block where the oil pressure switch used to be. (This is the hole via which oil is supplied by the engine for bypass filtration. The oil pressure switch is relocated.) It’s critically important that the thread in this hole is not damaged in any way. Never assume that the thread of a component that you’re trying to use will automatically match the thread in the hole. Instead, it’s very important to test very carefully and gingerly to see if the thread is compatible. There are many different thread types around so the possibility of incompatibility and subsequent stripping of the thread of the hole in the engine block should not be ignored. If you damage the thread of this hole you are going to cause serious problems for yourself which will require professional expertise to fix.

Prevent oil leaks with Teflon tape on all threaded fittings…

Prevent oil leaks from occurring by using Teflon tape on all threaded fittings through which oil is flowing. Without the use of Teflon tape it’s highly likely that oil leaks will occur, especially because the bypass filtration system is operating under pressure. The following is the correct way to use Teflon tape on the threaded fittings:

- Ensure that the thread to which the Teflon tape is being applied is clean.

- Don’t apply Teflon tape to the first 3mm of the thread. This is important so as to prevent the tape getting inside the fittings and contaminating the engine oil that flows through them. The tape should rather remain trapped and unexposed between the threads being screwed together.

- Apply the Teflon tape in the opposite direction to the direction of the thread. Otherwise the tape will bunch up and be ineffective when the matching fitting is screwed onto the thread.

- Be sure to pull the tape firmly into the thread as it is being applied.

- Because Teflon tape is so thin, it’s necessary to apply more than three revolutions of tape to get a good seal. A good number of revolutions of tape to apply is seven.

Use flare-nut spanners to avoid damaging the oil hose fittings…

Use flare-nut spanners on the hexes on the oil hose fittings to avoid rounding or deforming the hexes.

Don’t over-tighten any threaded fittings…

Don’t over-tighten any threaded fittings through which engine oil flows. Over-tightening can easily lead to the fittings distorting and leaking engine oil as a result of this distortion. All that is required is to tighten a fitting until the thread bottoms out and then tighten it up another eighth to a quarter of a turn so that it feels secure.

Obviously the benefits of bypass engine oil filtration are massive. Any motoring enthusiast instantly recognises the total superiority of running an engine on oil that’s always immaculately clean. It’s an excellent way of avoiding ever having to get the engine rebuilt because virtually no wear and tear takes place inside the engine to necessitate a rebuild. The performance of an engine that’s continually running on immaculately clean oil is much more lively than that of an engine using conventional full-flow filtration alone and running on contaminated oil, not to mention much smoother and quieter.

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Engine Bay

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Oil Pickup

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Mounting - Side View

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Mounting - Top View

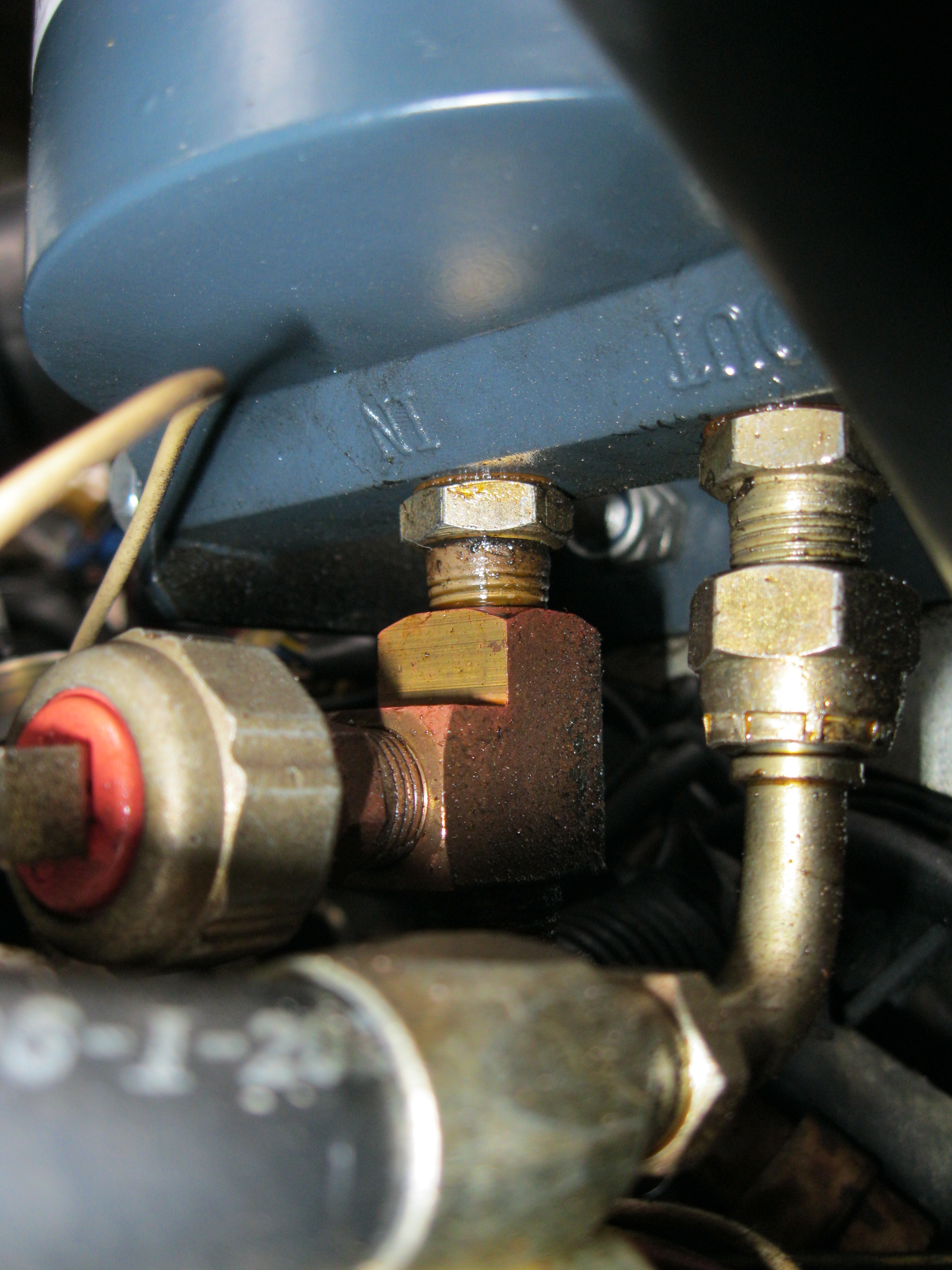

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Oil Pressure Switch Inlet - Outlet Hose - Side

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Oil Pressure Switch Inlet - Outlet Hose - Bottom

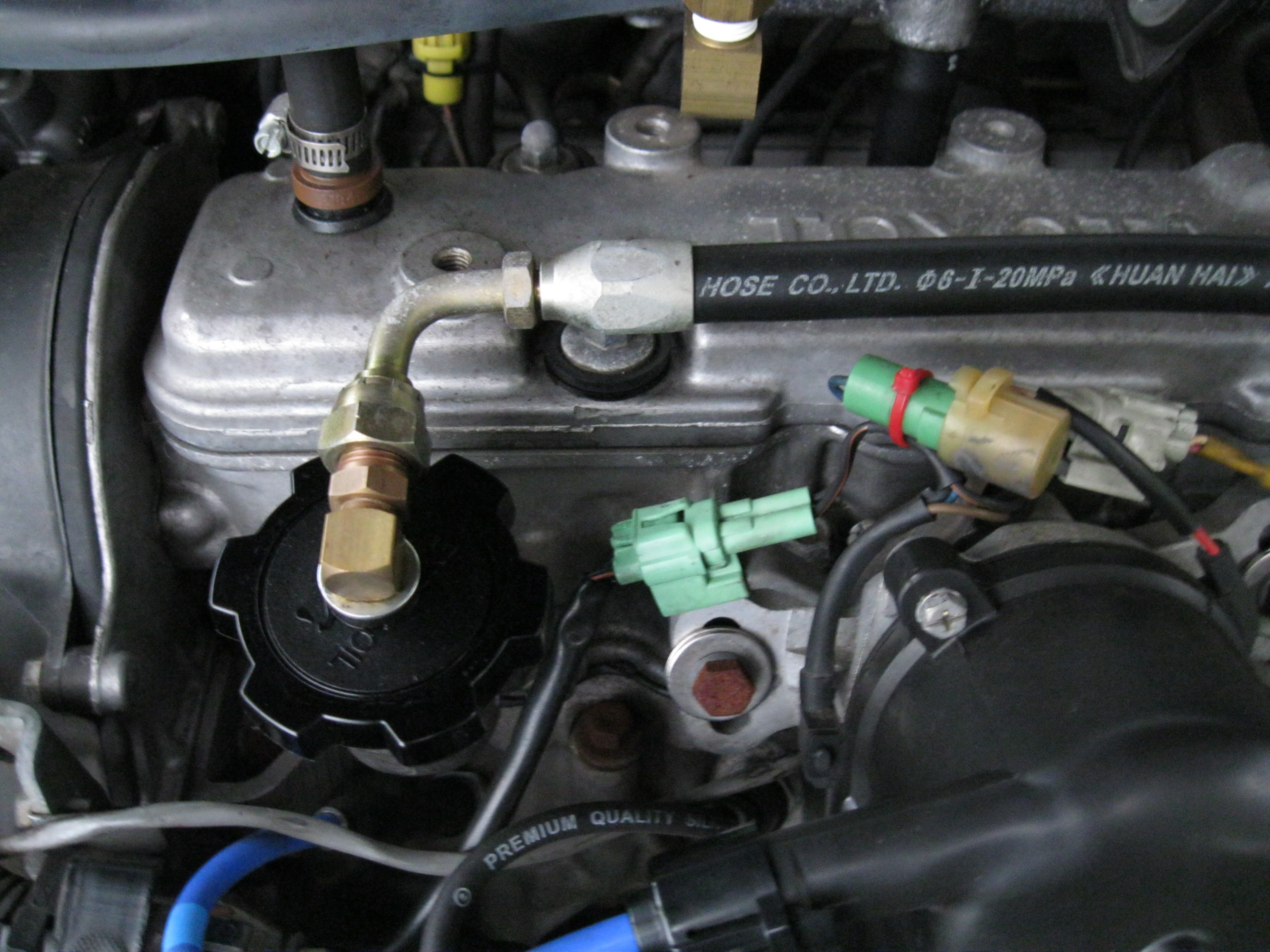

Jackmaster Bypass Engine Oil Installation - Toyota Camry 1986 SV11 - Oil Return

Copyright 2018 Andrew Mackinnon. All rights reserved.